In a groundbreaking development for the textile industry, C.L.A.S.S., an advocate for sustainable innovation, proudly highlights the achievements of its partner, ERCA Textile Chemical Solutions, with their latest innovation, REVE…

Menu

New collaborations with premium brands and high-tech designs, the ISO 14001certification awarded to the URAGO plant and the subscription to the Greenpeace Detox Campaign: Lanfranchi Spa’s positioning marks a step forward and combines the strength of creativity with a responsible mission for the future.

Lanfranchi’s production aims at being always closer to the costumer; this is the reason why, a cou-ple months ago, a 3D printer was introduced in the company, in order to create exclusive prototypes of unique shapes, tailored to the costumers, in very little time.

A care for customers that, together with high quality and responsibility, makes them unique in the market, attracting brands like Stella McCartney and Geox.

In keeping with her dedication to responsible material selection, Stella McCartney has selected a new eco-smart zipper for her RTW woman trouser collection. Made by Italian manufacturer, Lanfran-chi, these new zippers are 100% smart, since the metallic parts that meet the strict Detox and Oeko-Tex criteria are combined with organic cotton ribbons dyed during a GOTS-certified.

For their new SS 2017 NEW:DO outerwear collection, Geox chose instead the T3 and T5 stainless steel zippers with a Newlife™ ribbon in 4 colors. A clever quest for essence brought the company to choose Newlife™, the result of the High Tech Conversion Model that exclusively transforms fully traceable used plastic bottles into an incomparably qualitative and high-tech polymer during a fully mechanical, non-chemical process, all Made in Italy.

Lanfranchi Spa presents an innovative model in the fashion industry, based on 130 years of experience and on an artisanal quest for perfection. Lanfranchi’s zipper production is totally integrated, from weaving to sewing, all the way through dying, shearing, fusion, electro-plating and assembling. Even the machineries are Made in Italy and meet all the Italian and European regulations about environment, work safety and respect of the workers. The products have been Oeko-Tex-certified for more than 10 years and today they also meet the Standard 100 class I re-quirements, the strictest on products intended for children. Furthermore, the Urago (BS) plant was awarded the ISO14001 certification.

Lanfranchi Spa presents an innovative model in the fashion industry, based on 130 years of experience and on an artisanal quest for perfection. Lanfranchi’s zipper production is totally integrated, from weaving to sewing, all the way through dying, shearing, fusion, electro-plating and assembling. Even the machineries are Made in Italy and meet all the Italian and European regulations about environment, work safety and respect of the workers. The products have been Oeko-Tex-certified for more than 10 years and today they also meet the Standard 100 class I re-quirements, the strictest on products intended for children. Furthermore, the Urago (BS) plant was awarded the ISO14001 certification.

Spiber Inc. with its “Brewed Protein™” materials is a game changer in the fashion industry

C.L.A.S.S. Material hub is our section dedicated to producers of innovative ingredients: fiber, yarn, fabri…

A project by Venezia da Vivere and a capsule collection made in Bemberg™ fabrics, designed by Tiziano Guardini with the illustrator Jacopo Ascari.

May 2023 – Bemberg™ by Asahi Kasei, the unique fiber ob…

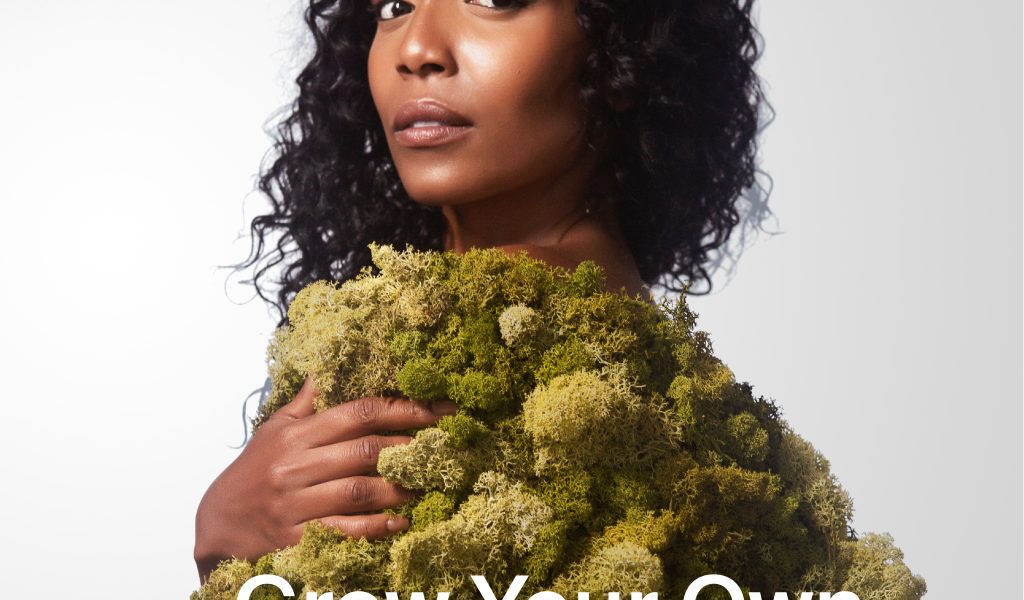

The award, now in its third edition, was set up by Connecting Cultures and C.L.A.S.S. with the aim of creating new visual imagery and innovative communication models in sustainable fashion

“Grow Your Couture” by Piero D’angelo, th…

Our CEO and Founder Giusy Bettoni has been really pleased to attend the 2nd Stakeholder Advisory Board Meeting of the MY-FI project held in Barcelona on May 4th at Leitat Technological Center!

We had the chance to meet the project members a…

Today we are happy to introduce you our new partner in our PROcess x PROgress category: REVECOL® by ERCA

As demonstration of ERCA TCS’s commitment towards responsible innovation, but also thanks to the important appreciation of its R&…

C.L.A.S.S. has always been committed to fostering and activating positive change in the fashion industry, while keeping contemporary consumers informed. This approach is perfectly aligned with the one of Challenge the Fabric that…

C.L.A.S.S. Material hub is our section dedicated to producers of innovative ingredients: fiber, yarn, fabric, leather and accessories.

Today we are happy to introduce you our new partner:

Pozzi Electa S.p.A.Pozzi Electa…

C.L.A.S.S. Material hub is our section dedicated to producers of innovative ingredients: fiber, yarn, fabric, leather and accessories.

Today we are happy to introduce you our new partner: Marini Industrie.

Marini Indust…

ROICA™ V550: the first Degradable Stretch solution for a New Generation of Denim

April 2023 – The international eco-tech yarn innovator and manufacturer ROICA™ by Asahi Kasei leads the way in circular stretch inno…

Since 2007 we have been advocating for a new generation of fashion where the fusion of design, innovation, communication and responsibility shapes an informed and competitive business, able to play both at an economic and social level.…

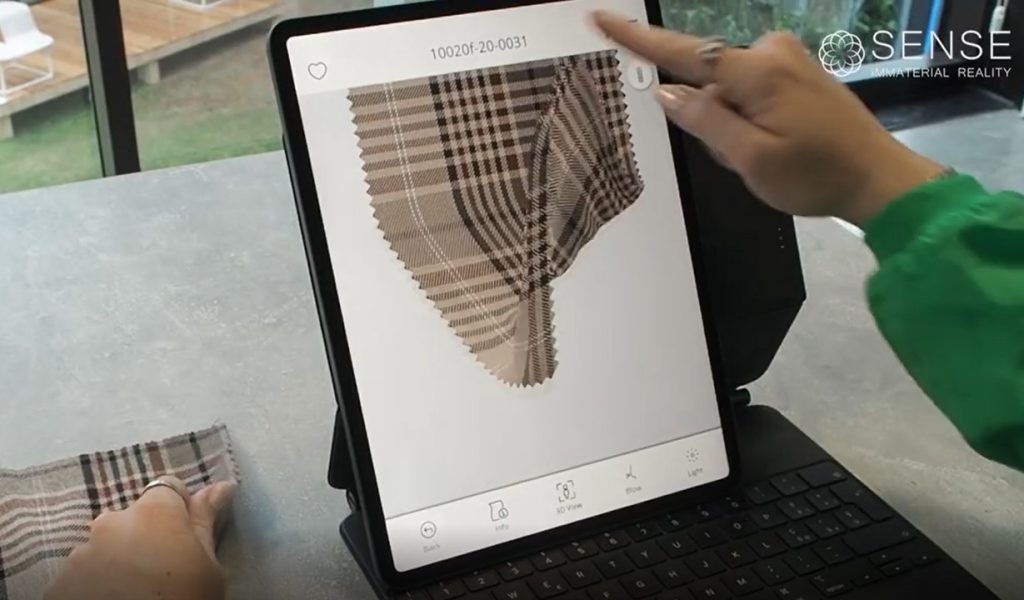

C.L.A.S.S. Future Devices is our area reserved for the new frontiers of digital communication: from virtual reality and haptics to blockchain platforms.

Today we are happy to introduce you our new partner:

Sense – im…