In a groundbreaking development for the textile industry, C.L.A.S.S., an advocate for sustainable innovation, proudly highlights the achievements of its partner, ERCA Textile Chemical Solutions, with their latest innovation, REVE…

Menu

What is the Cradle to Cradle certification? Why choose it and how to get it? How this certification can improve the textile industry? Lewis Perkins, Senior VP – Development and Textiles & Apparel at the Cradle to Cradle Products Innovation Institute – clearly answered all these questions.

Can you explain in few words what is Cradle to Cradle?

Lewis Perkins: «Cradle to Cradle is a set of design principles outlined by Dr. Michael Braungart and William McDonough in their book, Cradle to Cradle: Remaking The Way We Make Things, which looks to nature for the design of products.»

What is the function of the Innovation Institute?

L.P.: «The Cradle to Cradle Products Innovation Institute verifies the product assessment work and issues the certification mark to manufacturers. We oversee the development of the standard with an assembled board of experts (Certifications Standards Board). We also build the brand of the certification mark through focused campaigns and strategic partnerships, adding value to the companies who implement cradle to cradle optimization.»

Who is your target?

L.P.: «Our target is all product manufacturers. We envision a world with safe and healthy products, where the materials used in products will continue to be used in future generations of products, using renewable energy, water stewardship and social fairness. In this scenario, growth is good.»

There are many kind of certifications: Why choose C2C?

L.P.: «Cradle to Cradle is a continuous improvement, multi-attribute program. We do not certify products once and go away. It is about the brand, manufacturers, or mill, become engaging in redesigning the way they make their products and moving toward an end goal. There is a path and a destination in sight. This makes our certification mark become more of a relationship to the products and companies as they scale up from basic, bronze, silver, gold to the ultimate goal, platinum level products.»

What is the situation in the textile world?

L.P.: «The Textile Industry is unique in many ways, but when Cradle to Cradle design principles are applied, the work is not tremendously different. We looks across the supply chain and we see issues of social fairness, water stewardship, the use of chemicals of concern, and ultimately a lot of waste. With Cradle to Cradle design, waste = food. Everything becomes a nutrient for the next system. So in textiles, we want to make sure that both pre-consumer and post-consumer materials find a use in future lives.»

How the C2C certification can improve the textile industry, why is important?

L.P.: «Puma launched the Incycle Collection this winter. This is a Cradle to Cradle certified collection (at the basic level). These products are designed so that their materials may either be composted as a biological nutrient or become recycled into the technical nutrient system. Puma is partnering with I:CO to provide in-store “Bring Me Back” bins for product recollection and end of the first useful life. They are working to launch the next collection of Incycle products and the intention will be to go up the certification scale, improving upon each seasons’ innovations. We love this leadership as we want to inspire more companies to create innovations to use yarns and fibers again and again. We need these valuable materials back. Zippers, buttons, clasps, packaging… It all becomes part of redesign so that we ensure nothing goes to landfill. Cradle to Cradle certification also looks at the chemicals and dyes used in the production of apparel. We don’t want harmful or potentially harmful materials in manufacturing, leaching into the communities where they are made, into our homes or on our bodies during product life use, nor in the material compost or recycling phase. Companies working with our standard will be ensuring that chemicals of concern have been removed from the process and the product.»

When a company ask for the certification, what exactly happens? What is the process to get it?

L.P.: «A company will be directed to an accredited third-party assessor of Cradle to Cradle certification. In that initial assessment, all aspects of the product creation will be looked at – spinning, weaving, cutting, sewing, etc… Cradle to Cradle certification assesses the product of your product along the supply chain. Once any opportunities for optimization are embarked upon or addressed (if necessary), the company will work with that assessor to have their product taken through the paperwork required. This work is then submitted to the Institute who verifies the work and issues the certification mark. Readers can learn more about what is involved in product certification by reading the Standard overview here.»

What about the label and let this certification be recognisable by the end user?

L.P.: «The brand will be allowed to use the certification mark (label) only on products that achieve a score of bronze level and higher. At the basic level, we have begun the work and the company may refer to their certification in marketing materials. This is to ensure the quality of the standard and not confuse consumers in thinking a basic level product is perfect. This is about continuous improvement. With brands like Puma engaging in certification and marketing their efforts, Cradle to Cradle is becoming more recognized by consumers and will continue to become so. Our vision is to make Cradle to Cradle product certification the preferred standard for brands and other manufacturers and for consumers who will look for the mark to ensure a product which is better for people and planet. We are building several consumer facing campaigns now to improve the recognition of our mark and the work is represents.» www.c2ccertified.org

Interview by Laura Molteni

Spiber Inc. with its “Brewed Protein™” materials is a game changer in the fashion industry

C.L.A.S.S. Material hub is our section dedicated to producers of innovative ingredients: fiber, yarn, fabri…

A project by Venezia da Vivere and a capsule collection made in Bemberg™ fabrics, designed by Tiziano Guardini with the illustrator Jacopo Ascari.

May 2023 – Bemberg™ by Asahi Kasei, the unique fiber ob…

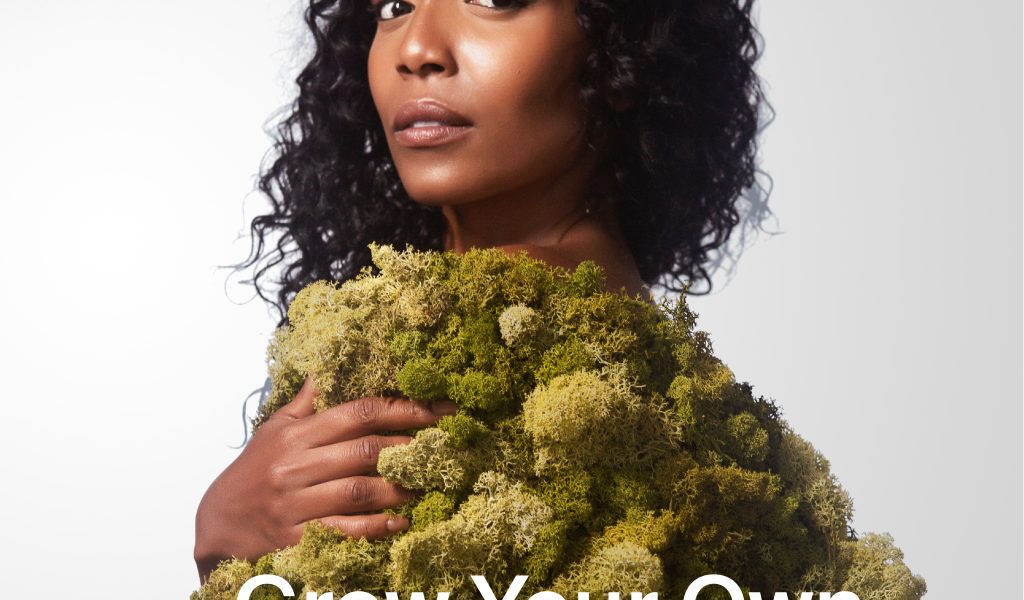

The award, now in its third edition, was set up by Connecting Cultures and C.L.A.S.S. with the aim of creating new visual imagery and innovative communication models in sustainable fashion

“Grow Your Couture” by Piero D’angelo, th…

Our CEO and Founder Giusy Bettoni has been really pleased to attend the 2nd Stakeholder Advisory Board Meeting of the MY-FI project held in Barcelona on May 4th at Leitat Technological Center!

We had the chance to meet the project members a…

Today we are happy to introduce you our new partner in our PROcess x PROgress category: REVECOL® by ERCA

As demonstration of ERCA TCS’s commitment towards responsible innovation, but also thanks to the important appreciation of its R&…

C.L.A.S.S. has always been committed to fostering and activating positive change in the fashion industry, while keeping contemporary consumers informed. This approach is perfectly aligned with the one of Challenge the Fabric that…

C.L.A.S.S. Material hub is our section dedicated to producers of innovative ingredients: fiber, yarn, fabric, leather and accessories.

Today we are happy to introduce you our new partner:

Pozzi Electa S.p.A.Pozzi Electa…

C.L.A.S.S. Material hub is our section dedicated to producers of innovative ingredients: fiber, yarn, fabric, leather and accessories.

Today we are happy to introduce you our new partner: Marini Industrie.

Marini Indust…

ROICA™ V550: the first Degradable Stretch solution for a New Generation of Denim

April 2023 – The international eco-tech yarn innovator and manufacturer ROICA™ by Asahi Kasei leads the way in circular stretch inno…

Since 2007 we have been advocating for a new generation of fashion where the fusion of design, innovation, communication and responsibility shapes an informed and competitive business, able to play both at an economic and social level.…

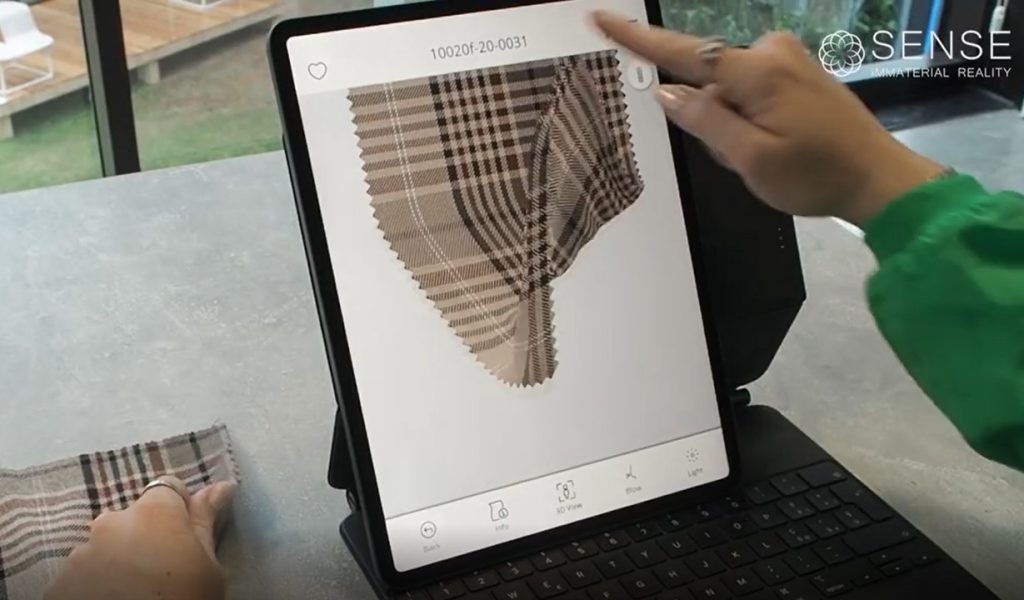

C.L.A.S.S. Future Devices is our area reserved for the new frontiers of digital communication: from virtual reality and haptics to blockchain platforms.

Today we are happy to introduce you our new partner:

Sense – im…